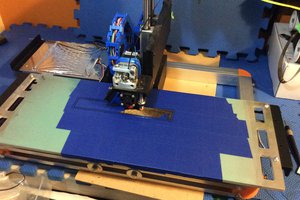

Plotter Prototype:

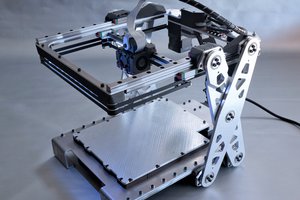

Finished 3D Printer:

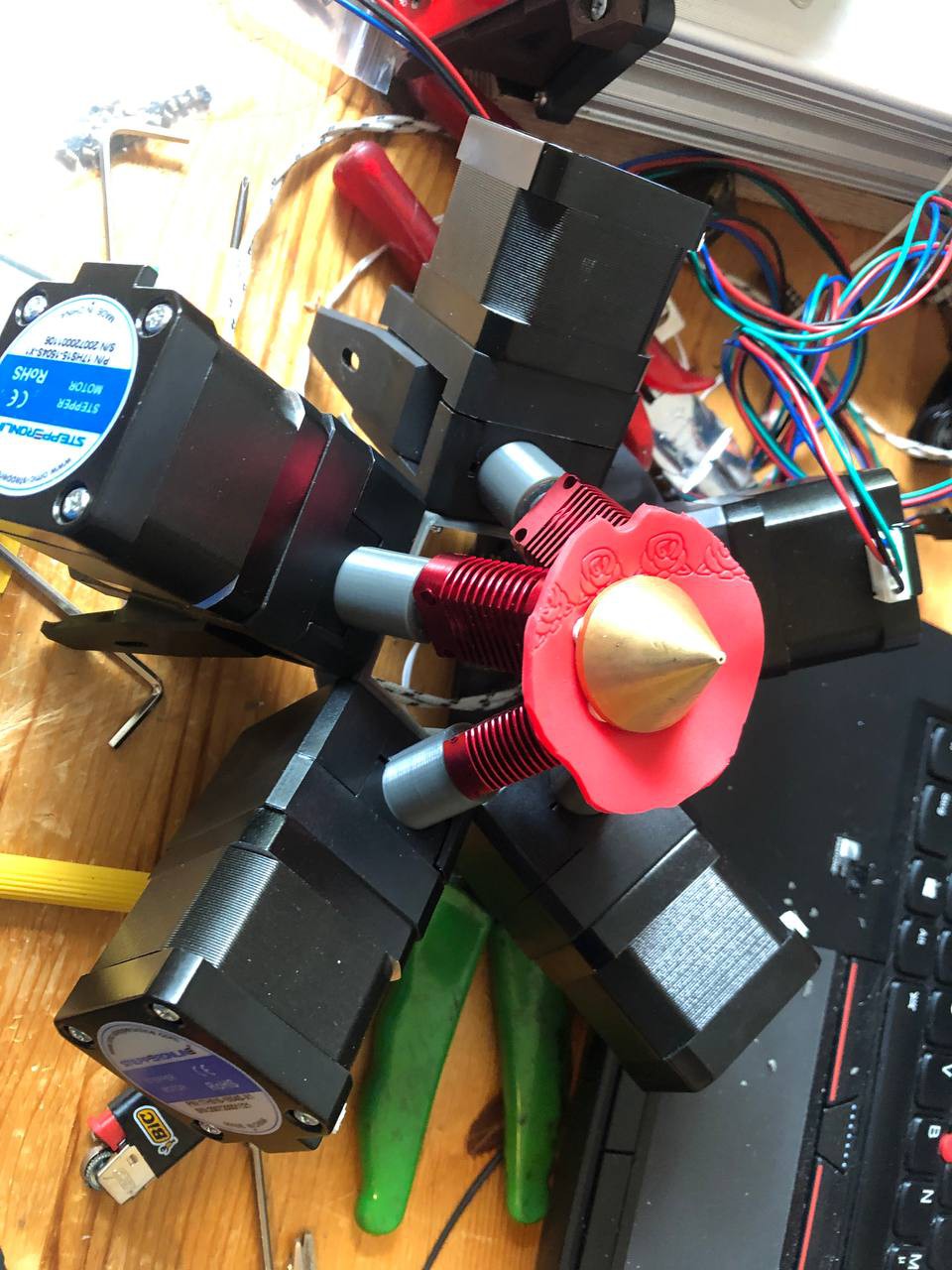

Toolchanger config:

Diamond hotend turntable timelapse:

I tried gluing the GT2 belts to the discs. Superglue holds well, but not sure how long it will last and glueing is too much of a hassle. Printing in PLA is easier, though louder.

Printed TPU belts might work if it's not too soft or it needs more mounting holes.

Omitting them alltogether and using some sort of contact wheel from an old cassette deck or an inkjet paperfeeder might work as well with low acceleration.

All polar printers have some nice timelapse or scanning capabilities, since the print is already on a turntable.

Multi-Extruder and parallel printing is another option that has been explored by Tyler Anderson's Theta printer https://hackaday.io/project/812-theta-printer

The Formulas for cartesian to bipolar coordinates are based on his bipolar Marlin fork. https://github.com/unlimitedbacon/BipolarMarlin/

He wrote a nice script to visualize the conversion,

unfortunately I couldn't get it to run due to the old python and sfml version being used.

If someone gets it to run, please let me know. https://github.com/unlimitedbacon/SpinSim

Brent K made another design with tool changing abilities. He used a clever way to rotate the printbed around the axis of the base platter. This way both motors are stationary.

There are more shared concepts of a bi-polar 3D printer.

The oldest one I could find is from Trent Tobler, aka BeagleFury in 2006.

https://web.archive.org/web/20100726173538/http://builders.reprap.org/2006/08/dual-disk-sketch.html

He posted more info of his printer 'RepOlaRap' on the reprap forums.

https://reprap.org/forum/read.php?152,32343,33058#msg-33058

Another thanks to Robert Menetray who provided me with all the files of his stacked polar printer.

https://web.archive.org/web/20150122132445/https://robertmenetray.com/impresora-3d-bipolar-con-enlace-sarrus

Print speed at the center needs adjustment and I ordered a hollowed shaft stepper to route the pen holder through, allowing for the full rotation of the print bed, but limiting the overall build size..

heinz

heinz

Benchoff

Benchoff

ken.do

ken.do

dekutree64

dekutree64

Malte Schrader

Malte Schrader

jou should sell these 3d pritners