EXCITERS & TACTILE TRANSDUCERS 101

An Introduction

WHAT IS AN EXCITER OR TACTILE TRANSDUCER?

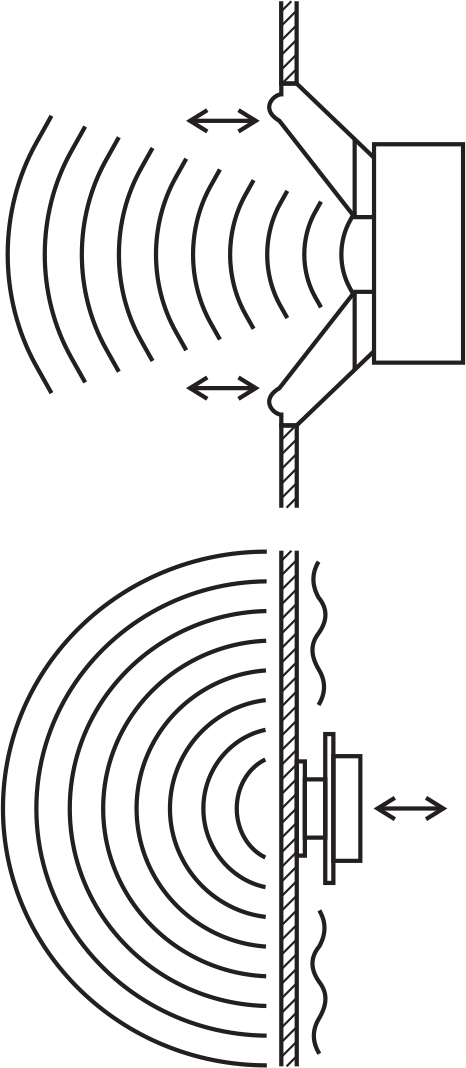

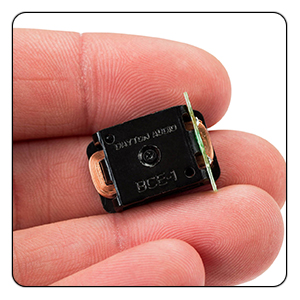

Quite simply, a sound exciter is a loudspeaker without the frame and cone. Exciters function by replacing these components with a rigid surface which vibrates in order to create sound. This is why exciters are often referred to as the “invisible” or “universal” speaker, as they can often be placed on surfaces not conducive to traditional speakers or in locations where hidden speakers are desired.

HOW DOES AN EXCITER WORK?

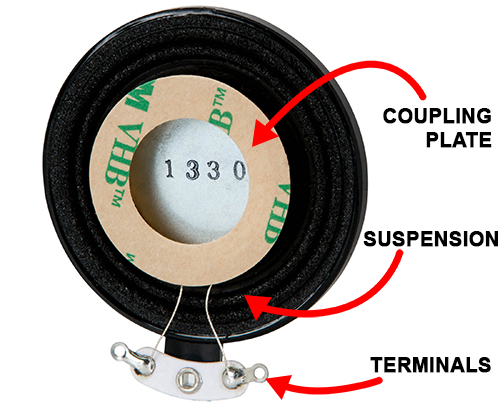

Exciters are comprised of a motor assembly, a voice coil, a suspension system, electrical connection terminals, and an adhesive ring or coupling plate which joins the exciter to the mounting surface. When a signal is transmitted to the exciter, the unit begins to vibrate at the frequency of the signal and those vibrations transfer through the exciter’s mounted surface thus emitting sound.

REAR VIEW

SIDE VIEW

FRONT VIEW

WHY USE AN EXCITER?

Surface exciter technology provides a universal, cost-effective alternative to loudspeakers, allowing for sound reproduction virtually anywhere it is desired. Issues such as weather, space constraints, vandalism or visibility can be avoided or minimized with the use of a sound exciter. Additionally, exciters may be used in a host of DIY executions to easily add sound to an existing non-audio specific project or create a portable speaker system. As long as a desirable surface is available for mounting and an amplification source can be added, exciters are the go-to product for a host of applications.

WHERE TO USE AN EXCITER?

One of the most frequent questions regarding exciters involves the placement substrate and resulting sound. There is no simple answer for sound reproduction because there are a host of factors which affect how the sound exciter will react in an individual application. Because exciters perform by vibrating against the surface by which they are mounted, the surfaces themselves can and will affect the end result.

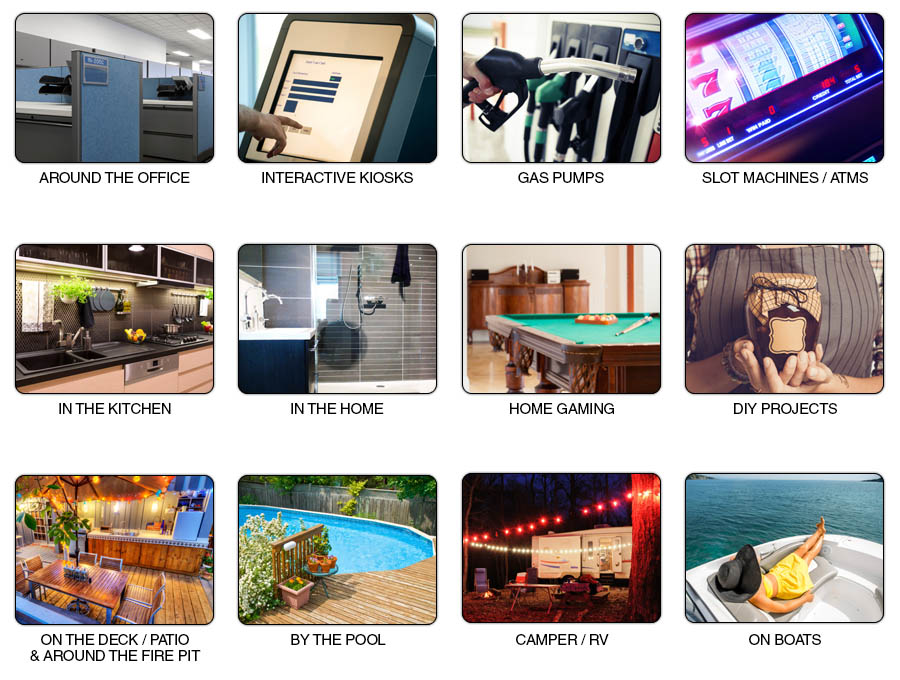

For example, mounting an exciter onto glass provides a much different sound than mounting to a sheet of foam core. The size of the surface the exciter is mounted to, the specs of the exciter itself, and the resulting motion of the surface all factor into the overall performance and sound output, therefore no one singular answer can be provided. Even though it seems like quite the grey area, the ability to leverage flexibility with installation outweighs the need for concrete specifications. This is why exciters are a popular choice in a variety of applications including:

- Home theater and multi-room audio where visibility is a concern

- Boats, bicycles, automobiles, airplanes and other modes of transportation

- Electronic gaming machines, ATMs or kiosks which utilize sound

- Retail product displays, advertising signage or multimedia exhibits

- Bathroom installations including tubs and shower enclosures

- Commercially distributed audio

- DIY projects where sound is desired as a secondary component (ex. a photo frame which doubles as a Bluetooth speaker)

- Schools and offices, specifically within conference rooms and behind white boards, etc.

- Outdoor installations where weather concerns are a factor: decks, patios, porches, fire pits, sheds, planters, barns and more

- Kitchen cabinets, bathroom cabinets, closets, furniture, walls and other locations in the home

- Portable surfaces including coolers, folding chairs and tables, lunch boxes, wagons, etc.

You can add sound to virtually any location with a mountable surface!

EXCITER SELECTION AND TYPES

Once a project has been identified and a mounting material has been sourced, the next step is assessing which exciter would work best in the application. There are more than 25 different varieties of Dayton Audio exciters, each with their own features and benefits. A topline overview is provided below to assist with determining which exciter will be perfect for your next project.

TYPES OF EXCITERS

Selecting an exciter involves a number of factors including application location, surface substrate, size and weight of the mounting surface, coverage area and desired result. To assist with narrowing down which exciter to choose, we have provided simple descriptions for a few of the most common types of exciters. Please note certain exciters span across multiple categories, therefore it is best to review all benefits when selecting which exciter best meets the needs of your project.

Coin Type

As the name suggests, COIN TYPE exciters are smaller and typically less than 1” in size. They are perfect for applications on smaller surfaces or in compact areas where space is limited. Coin type exciters are often used in toys, monitors, small glass enclosures, etc.

Bone Conducting

Instead of moving air, BONE CONDUCTING exciters convert electrical signals into clean mechanical vibrations which stimulate the bones in the ear. The brain then interprets this stimulus as clear sound. These exciters are ideal for applications where the listener will be in contact with the surface the exciter is mounted to, such as massage tables, reclining chairs, etc.

High Power

When increased sound performance is required, HIGH POWER exciters provide the specialized mounting provisions and assembly needed to deliver maximum output. These exciters may be secured to a wide range of materials and in multiple directions as well as attached to moving objects.

Extended Mount

EXTENDED MOUNT exciters are designed for projects featuring a larger mounting surface or a need for robust mounting due to power handling. Often leveraged in home projects such as doors, drop ceilings, large windows or decks, these exciters provide an extended frame or stabilizing legs for added contact between the exciter and the surface.

Haptic Feedback

Add the sense of touch to computer applications with HAPTIC FEEDBACK exciters. Their ultra-compact design enables incorporation into a variety of small-scale applications such as virtual reality where tactile response is desired.

Bass Shaker

The most notorious tactile transducer, BASS SHAKERS work on the principle that low frequency bass is mostly felt and not heard. When mounted to a couch or chair, BASS SHAKERS add a fourth dimension to the listening experience as they transfer electrical energy to mechanical energy. Some sound waves are simply too low to hear and therefore are felt through the body, delivering high impact response in home theater and gaming applications. The bass shakers also reinforce sound waves in the bass region that you can hear by adding the "feeling" part of the experience.

MATERIAL SELECTION FOR EXCITERS

In many surface exciter applications, the material of the surface to be excited and the edge termination of the surface are dictated by external factors. However, these selections can be optimized to provide improved audio quality over a wider bandwidth from the hidden ‘speaker’ formed by the exciter and the panel. The material that the exciter is used with has the greatest impact on the frequency range and efficiency of the exciter, which is why a generalized frequency or impedance response curve is not typically published for exciters.

The ideal material for mounting an exciter is a thin, lightweight sheet of material with high compressive strength and moderate to high bending strength. The compressive strength of the material has the greatest effect on the treble extension of the resulting ‘speaker’ (affecting ‘detail’ and ‘air’), while the bending strength of the material influences the midrange and low frequency efficiency of the ‘speaker’.

The amount of acoustic output from the panel over its effective bandwidth is determined by the weight of the panel material and the available force from the exciter. For thicker or heavier materials, a larger and more powerful exciter may be needed, or multiple exciters may be used. Whenever possible, the weight of the surface to be excited should be minimized.

Excellent materials to use for exciter mounting include:

- Aluminum, Nomex/Kevlar, or resin-impregnated paper honeycomb sandwich composites

- Structural or syntactic foam sandwich composites (e.g. Rohacell)

- Fabric-reinforced phenolic plastic panels

- Fiberglass-reinforced resin panels

- Corrugated or honeycomb cardboard sheet

- Corrugated plastic ‘signboard’ material

- Foam-core poster board with paper backing

Other materials which are less ideal but still workable include:

- Unreinforced plastic panels

- Mylar sheet

- Plexiglas or Lexan sheet

- Glass windows

- Mirrors

- Acoustic drop-ceiling tiles

- Wallboard

- Plywood/MDF/OSB sheets

Materials which may not give desirable results:

- Metal panels

- Metal structural members

- Concrete

- Wooden beams

- Soil

EXCITER PLACEMENT AND INSTALLATION

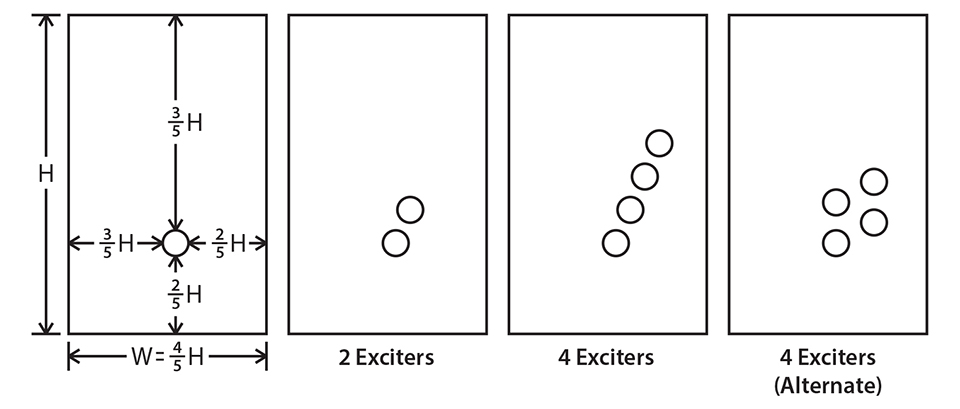

Once the mounting surface material, shape, and size are known, the exciters can be placed. Exciter placement is critical to achieving uniform excitation of the surface while maintaining wide dispersion. For the best results, exciters should be placed near the center of the mounting surface, but should be offset from each edge of the surface so that the distance from the exciter to the edge is not an even multiple of the distance from the exciter to another edge of the panel, in order to avoid the buildup of standing waves.

For mounting exciters to a flat rectangular panel (a common application), the width of the panel should be less than 4/5 of the height, or vice versa, and good results will be given with the exciter mounted a distance of 2/5 of the panel width from one side of the panel, and 3/5 from the other side of the panel, with the same relationship used for exciter placement with respect to the panel height. This relationship will provide a satisfactory offset to reduce the buildup of standing waves on the panel.

If multiple exciters are needed for a panel or surface, it is not recommended to space the exciters evenly across the surface. This will result in very narrow sound dispersion at upper midrange and treble frequencies. Instead, place the exciters together in a group, with exciters at unequal distances from the panel edges and from one another.

Installation of most exciters is simple. An adhesive pad is provided with some exciters, which should be applied to a smooth, clean area of the surface. For other exciters that provide screw mounting via a mounting plate, it is still recommended to apply an adhesive such as “super glue”, hot melt glue, or double-sided tape to the mating surface of the mounting plate in addition to the mechanical fasteners, to avoid rattling or buzzing of the mounting plate against the surface. If attenuation of upper frequencies is desired (typically not desirable), this can be achieved with an inductor electrically in series with the exciter, or by adding a compliant pad (such as a sheet of rubber) between the exciter and the surface.

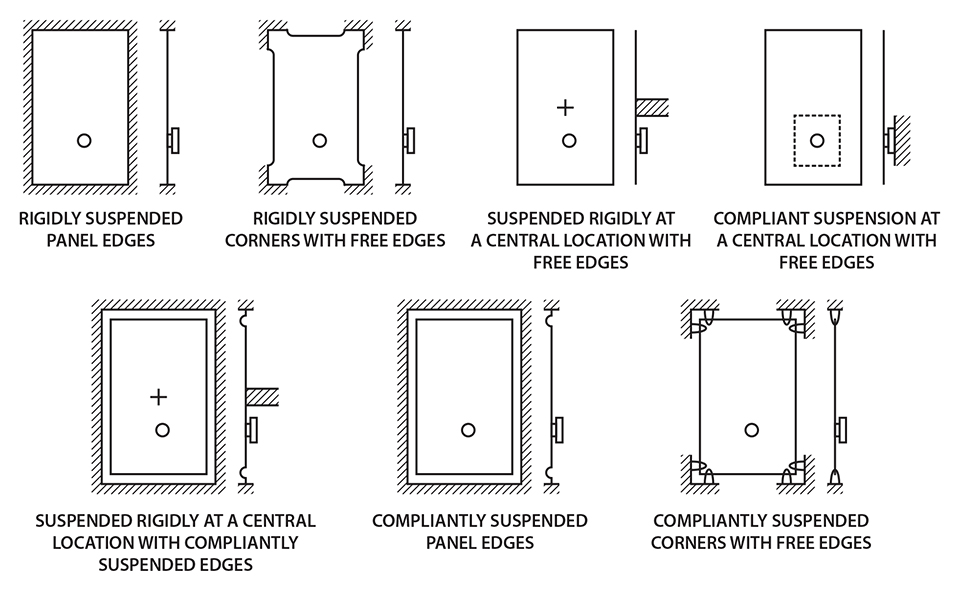

Edge Termination and Damping

As described earlier, prior to being radiated into the room by the vibrating panel surface, acoustic waves first travel through the material of the panel itself, as though it were its own acoustic environment, with its own speed of sound. When these traveling waves in the panel material encounter a different acoustic impedance (such as a different material or a panel edge), some or all of the traveling wave is reflected and propagates in a new direction across the panel. In some instances it may be desirable to reduce this reflected energy to improve clarity and transient response, and this can be achieved through controlled termination of the panel edge, or by applying a soft damping material to the panel itself.

The benefit of compliantly suspending part or all of the panel is a reduction in the internally reflected energy, because some of the energy is transmitted into the compliant material and does not get reflected. Compliant suspension of the panel edges may be accomplished using a soft material like foam tape, a silicone adhesive bead, or a flexible rubber member.

Other means can be used to control the vibration of the panel. For example, the corners of a rectangular or polygonal panel may be rounded to help reduce long-decay reflections. Linear or curved braces, point masses, and damping elements (such as felt buttons) may also be added to the panel to control its vibration, but these are generally not necessary except in highly-optimized applications. Engineering modeling software can aid in the application of these more advanced panel damping features, or the placement and use of these items can be determined experimentally.

Additional Tips

- Using a larger panel or installing the exciter to a larger surface will provide deeper bass response.

- A non-magnetic material should be chosen for the exciter mounting surface; mounting the exciter to a magnetic material may interfere with the magnetic circuit of the exciter’s motor assembly and impair performance.

- Suspending a panel at a central location will reduce bass response; exciter placement should be chosen to be between central mounting points and panel edges, instead of placing the exciter close to the central mounting point.

- Exciters are slightly less efficient than conventional loudspeakers. As a very rough guideline, expect to replace one speaker with two exciters in retrofit applications.

WIRING OF EXCITERS

Exciters may be used with any typical audio amplifier, using typical speaker wire. However, care should be taken to avoid overloading the amplifier with a low-impedance load. Because many exciter-based audio systems use multiple exciters, care should be exercised in wiring the exciters so the resulting load presented to the amplifier does not fall outside the amplifier’s minimum rated impedance.

When using multiple exciters, the units may be wired together in series or parallel to give an acceptable impedance load for the amplifier. When exciters are wired in series, their impedances add together (8 ohms + 8 ohms = 16 ohms). When exciters are wired in parallel, the impedance of one exciter is divided by the number of exciters (8 ohms / 2 exciters = 4 ohms). By creating groups of exciters wired in series, then wiring the multiple series groups in parallel, a wide range of impedances can be created from groups of many exciters. It is usually easiest to use this technique on even-numbered groups of exciters.

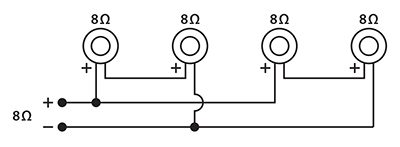

Below are some examples of series-parallel wiring to achieve desired impedances.

Example 1: Four 8-ohm exciters, wired for 8 ohms combined

Series Group 1: (8 ohms + 8 ohms = 16 ohms)

Series Group 2: (8 ohms + 8 ohms = 16 ohms)

16 ohms per series group / 2 series groups = 8 ohms total

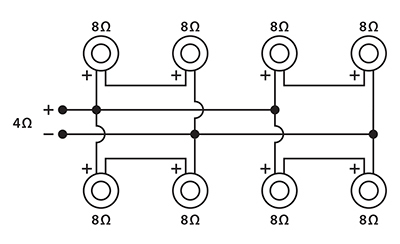

Example 2: Eight 8-ohm exciters, wired for 4 ohms combined

Series group 1: (8 ohms + 8 ohms = 16 ohms)

Series group 2: (8 ohms + 8 ohms = 16 ohms)

Series group 3: (8 ohms + 8 ohms = 16 ohms)

Series group 4: (8 ohms + 8 ohms = 16 ohms)

16 ohms per series group / 4 series groups = 4 ohms total

Note: Eight exciters with a nominal impedance of 8 ohms each cannot be wired via series/parallel for 8 ohms. See example 4 for a configuration using nine exciters with a nominal impedance of 8 ohms to achieve an 8 ohm final impedance.

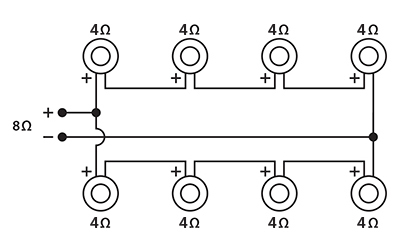

Example 3: Eight 4-ohm exciters, wired for 8 ohms combined

Series group 1: (4 ohms + 4 ohms + 4 ohms + 4 ohms = 16 ohms)

Series group 1: (4 ohms + 4 ohms + 4 ohms + 4 ohms = 16 ohms)

16 ohms per series group / 2 series groups = 8 ohms total

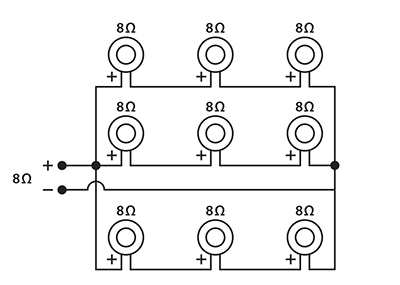

Example 4: Nine 8-ohm exciters, wired for 8 ohms combined

Series group 1: (8 ohms + 8 ohms + 8 ohms = 24 ohms)

Series group 2: (8 ohms + 8 ohms + 8 ohms = 24 ohms)

Series group 3: (8 ohms + 8 ohms + 8 ohms = 24 ohms)

24 ohms per series group / 3 series groups = 8 ohms total

For installations of multiple exciters, the connecting wire should not rest against the excited surface, in order to prevent noise from the wire buzzing against the surface. Where wire contacts the excited surface, it may be useful to add foam or felt to cushion the wire and prevent noise.

FAQs

Here are answers to some common questions regarding the use and application of exciters for audio:

1) Why select an exciter over a small speaker or conventional transducer?

Exciters work by vibrating the surface they are mounted to, creating a high-quality invisible speaker. Because the substrate/surface is being vibrated to produce the sound, there is no need for grills or openings in the surface, making the system more resistant to vandalism or weather ingress. The exciter's thin profile makes it perfectly suited for applications where there are space and depth limitations. In addition, the wide-angle sound dispersion from an exciter often exceeds standard loudspeaker performance.

2) Can two exciters on a single panel create stereo sound?

Yes! It is possible to use a left channel and right channel exciter on a single panel to achieve stereo sound. The quality of the stereo image will be determined by the distance between the left and right channel exciters, and the symmetry of their placement on the panel, just like the distance between conventional loudspeakers affects their stereo image. Groups of exciters can also be used for the left and right channels, following the placement recommendations in this article.

3) How can I increase the low frequency (bass) sound being produced by the exciter?

Bass and low frequency sound are enhanced greatly when using larger panels or increased areas of substrate. Additionally, using a heavier substrate will allow deeper bass to be achieved, but at the expense of reduced treble output.

4) Will the vibrations from an exciter be visible or "shake" the device or substrate the exciter is mounted to?

Because the vibrations are small and "fast", and propagate over a larger panel area than a typical speaker, the movement of the surface is usually not visible to the listener. As an example, should the exciter be used on video displays, the visual impact of sound being generated from the panel is unseen. Also, most electronic devices will be unaffected by the vibration of an exciter.

5) How are exciters mounted or affixed to surfaces?

Most exciters incorporate a mounting ring with peel-and-stick film adhesive that is used to mount the exciter to most any substrate or surface area. Prior to mounting, surfaces should always be prepared (clean and dry) to remove dust, oils or any other elements that may impede the bonding of the adhesive and surface areas.

6) Does placement impact the sound performance of the exciter?

Placement does impact the sound being produced by the exciters, and therefore prior to selecting a permanent location listening tests and audio testing is recommended. Exciter placement is covered in detail in Exciter Installation, but in brief, exciters that are offset to the side (not centered) on a panel provide the best sound experience. However, this may not always be the case as sound quality is subjective and can be perceived differently from listener to listener.

7) Can I attach exciters to ordinary surfaces (walls, ceilings, doors)?

Yes! Exciters can turn ordinary surfaces into high-quality speakers, and exciters can often be hidden behind or inside panels to provide sound from an invisible source. Unlike in-wall speakers, which interface directly with the air and require visible grilles to protect the drivers, an exciter sets the wall surface itself into motion to produce sound, so no grille is required. The surfaces that will give the best performance are those which are thin and light, like cabinet doors in a kitchen, or a fiberglass shower enclosure.

8) How does an exciter differ from a "bass shaker" device?

Exciters differ from "bass shakers" in two important ways. Normally, a bass shaker device will have an internal mass element inside a housing, and the reaction force from vibrating the mass creates the low-frequency bass vibrations. In an exciter, the mass of the motor structure remains stationary by its own inertia, and vibrating energy is transferred directly to the surface by the voice coil. Also, the design of a bass shaker is usually limited to low frequencies because of the large mass involved, while an exciter can produce the full range of sound because the moving mass is low. Choosing an exciter with a suspension system that is more "stiff" can increase the sound efficiency of the exciter and panel, while limiting low frequencies.